Description

Hastelloy C276 / UNS N10276 / ALLOY 276 / Hastelloy X

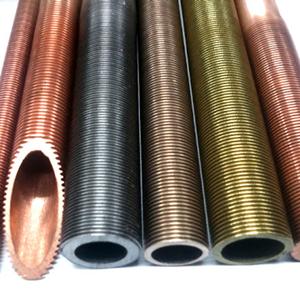

Hastelloy C276 UNS N10276 ALLOY 276 Hastelloy X is available in wide variety of shapes and forms including pipe, tube, fitting, flange, sheet, plate, round bar, forging stock, flat bar, wire, hexagon. The various forms of UNS N10276 from Hengyang Piping meet different critical standards like ASTM, ASME, DIN, EN and clients’ specification.

C276 tubing is a seamless or welded stainless steel pipe made from the alloy C276. This alloy is composed primarily of nickel, chromium, and molybdenum, providing exceptional resistance to corrosion from a wide range of aggressive media, including sulfuric acid, hydrochloric acid, and chlorine-containing environments. With its outstanding corrosion resistance and mechanical properties, alloy C276 tube is a reliable choice for demanding applications.

Alloy c276 tube features:

1. Corrosion Resistance: C276 tubing exhibits excellent resistance to corrosion, making it suitable for highly corrosive environments such as chemical processing, waste treatment, and pulp/paper production.

2. High Strength: The alloy C276 offers remarkable mechanical strength and toughness, allowing it to withstand extreme conditions, including high pressures and temperatures.

3. Versatility: C276 tube can be used in various forms, including seamless or welded pipes, and it can be easily fabricated and welded, enhancing its adaptability to different applications.

4. Wide Temperature Range: Hastelloy c276 pipe can operate effectively in temperatures ranging from cryogenic to elevated levels, making it suitable for both low-temperature and high-temperature applications.

5. Resistance to Crevice and Pitting Corrosion: The alloy's composition provides excellent resistance against crevice and pitting corrosion, preventing localized damage that can compromise the integrity of the system.

Alloy C276 UNS N10276 Chemical Composition

|

% |

Ni |

Cr |

Fe |

Mn |

C |

W |

Si |

S |

P |

Co |

Mo |

V |

|

Min |

Remainder |

14.5 |

4.0 |

|

|

3.0 |

|

|

|

|

15.0 |

|

|

Max |

16.5 |

7.0 |

1.0 |

0.01 |

4.5 |

0.08 |

0.03 |

0.04 |

2.5 |

17.0 |

0.35 |

Hastelloy C276 Physical Constants:

|

Density |

8.87 Mg/m³ |

|

Melting Range |

1325-1370 ℃ |

UNS N10276 Mechanical Properties:

|

Grade |

Tensile Strength, min, (MPa) |

Yield Strength, min, (MPa) |

Elongation in 2 in. or 50mm, min, % |

Hardness, max HRC |

|

UNS N10276 |

690 |

283 |

40 |

- |

Hastelloy C276 Application:

1. Pulp and Paper Production: Hastelloy C276 tubing finds extensive use in the pulp and paper industry. It is employed in equipment such as digesters, bleach plants, and chemical processing components, where resistance to corrosive chemicals is vital for efficient operation.

2. Pharmaceutical and Food Processing Equipment: Alloy C276 tube from Hengyang is highly sought after in the pharmaceutical and food processing industries. Corrosion resistance makes alloy c276 pipe ideal for handling chemicals, cleaning solutions, and food-grade materials, ensuring the integrity and safety of the production process.

3. Waste Treatment: Alloy c276 tube is widely used in waste treatment plants, where it withstands corrosive gases and liquids. Reliability of hastelloy c276 seamless pipe in such aggressive environments ensures longevity and efficiency in waste treatment processes.

4. Heat Exchangers, Evaporators, and Chemical Processing Components: UNS N10276 ALLOY tubing is widely employed in heat exchangers and evaporators, where it efficiently transfers heat between different fluids. Corrosion resistance and mechanical strength make c276 pipe suitable for various chemical processing components that require durability and reliability.

5. Sour Gas Well: C276 tubing is utilized in sour gas wells, which contain high levels of hydrogen sulfide (H2S) and other corrosive elements. The alloy's resistance to such aggressive conditions ensures the integrity and safety of the well operation.