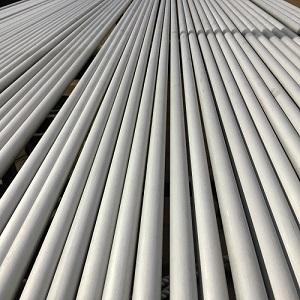

HENGYANG PIPING delivers high-performance austenitic ferritic stainless steel pipes and tubes engineered to excel in corrosive and high-stress applications. Our stainless steel tubes spans UNS S31254 (Super Austenitic), 316Ti/1.4571 (Heat-Resistant), Alloy 904L, and ASTM A688 TP304/304L Ultra-Long Tubes, crafted with a chromium-nickel alloy matrix for unmatched corrosion resistance, non-magnetic properties, and exceptional formability.

Certified to ASTM, EN, and ISO standards, our seamless steel tube solutions cater to industries demanding hygiene, durability, and precision—from chemical processing to medical equipment.

Stainless steel pipe types & features

1. Austenitic Stainless Steel Pipes

Material Composition: Chromium (18-25%), Nickel (8-20%), Molybdenum (2-6%) for enhanced pitting/crevice corrosion resistance.

Core Advantages:

Non-Magnetic & High Ductility: Ideal for deep-drawn components (e.g., sanitary fittings, medical instruments).

Cryogenic to High-Temperature Performance: Retains toughness at -196°C and resists oxidation up to 870°C.

Fire Resistance: 30-minute fire rating without additional coatings (per EN 1363-1).

Flagship Grades:

UNS S31254 (6% Molybdenum): For seawater desalination and chlorinated environments.

316Ti/1.4571: Titanium-stabilized for welding stability in chemical reactors.

ASTM A688 TP304L: Ultra-low carbon for welded food processing equipment.

2. Specialty Austenitic Solutions

Bright Annealed Precision Tubes: Mirror-finish surfaces (Ra ≤0.4µm) for pharmaceutical and semiconductor cleanrooms.

Sanitary Pipes 304/316: Electropolished, passivated, and certified to 3-A Sanitary Standards.

Thin-Wall & Coiled Tubes: Weight-optimized for aerospace hydraulic systems and heat exchangers.

3. High-Strength Austenitic Grades

STALA350/500/800 Series: Custom-engineered for structural weight savings:

STALA800: Yield strength ≥800 MPa, tensile ≥1000 MPa (offshore platforms, seismic-resistant architecture).

STALA500: Combines EN 1.4318 (301LN) lean chemistry with 25% elongation for automotive exhausts.

4. Complementary Ferritic Stainless Steel Tubes

Grades 430LI/434/444: Cost-effective, magnetic alternatives with moderate corrosion resistance:

Type 430: Basic ferritic grade for decorative trims and low-acid environments.

Type 444 (Mo-added): Chloride resistance for water heaters and HVAC condensers.

Stainless steel pipe applications

1. Chemical & Petrochemical: Acid transport pipes (Alloy 904L), heat exchanger tubes (S31805/253MA).

2. Oil & Gas: Subsea umbilicals (Super Duplex), refinery furnace tubes (Alloy 347H).

3. Medical: Sterile fluid transfer systems (Sanitary 316L), surgical tooling (Precision BA Tubes).

4. Construction: Fire-resistant structural hollow sections (STALA500), architectural façades.

WHY CHOOSE HENGYANG PIPING?

Technical Mastery

Material Customization: Tailor chemistry (e.g., nitrogen-enhanced 316Ti) for specific corrosion/mechanical needs.

Bespoke Dimensions: Roll-formed/press-brake sections up to 400x200x12 mm or custom U-bend configurations.

Rigorous Quality Assurance

NDT Compliance: Eddy current, hydrostatic, and ultrasonic testing per ASTM E213/A450.

Traceability: Mill test reports (MTRs) with EN 10204 3.1 certification.

Global Service Excellence

Design-to-Delivery Support: Laser-cut kits, surface finishing (2B, BA, #4), and ISO-certified packaging.

Rapid Turnaround: 10,000+ metric tons of ready stock for 72-hour dispatch.