Description

Integral low fin tubes are specifically designed tubes with enhanced surface area, accomplished through the process of integral finning. These tubes feature small fins that are seamlessly and mechanically attached to the outer surface, significantly increasing the heat transfer capability of the tube. The fins are precisely positioned, ensuring optimal turbulence and improved heat exchange performance.

Finned tubes advantages

1. Enhanced Heat Transfer Efficiency: The primary advantage of fin tubes lies in their remarkable heat transfer efficiency. The fins effectively augment the surface area, promoting better heat exchange between the fluid inside the tube and the surrounding environment. This translates to improved thermal performance and optimized energy consumption in heat transfer applications.

2. Compact Design: With their compact and efficient design, integral low fin tubes offer significant space-saving benefits. Their increased surface area allows for greater heat dissipation within a limited footprint, making them ideal for installations where space is a constraint.

3. Reduced Fouling: The finned structure of stainless steel finned tube heat exchangers mitigates the accumulation of deposits and fouling on the surface. This feature minimizes maintenance requirements and extends the operational lifespan of the tubes, resulting in cost savings and enhanced system reliability.

4. Versatile Applications: Finned copper tubing finds extensive applications across diverse industries. They are widely employed in heat exchangers, condensers, boilers, economizers, air coolers, and other thermal processes that demand efficient heat transfer. Whether it's industrial HVAC systems, power generation plants, chemical processing units, or refrigeration applications, integral low fin tubes deliver exceptional performance.

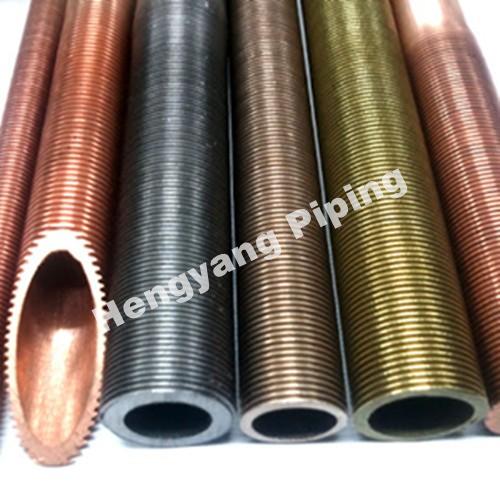

5. Material Flexibility: Our integral low fin tubes are available in a variety of materials, including stainless steel and copper. This allows you to choose the most suitable option based on your specific requirements, such as corrosion resistance, thermal conductivity, and operating conditions.

Integral Low Finned Tubes

|

Tube Material |

Stainless Steel, Copper, Carbon steel, Titanium |

|

Tube OD |

12.7~25.4mm |

|

Tube Wall Thickness |

1.0mm-5.0mm |

|

Fin Material |

------- |

|

Fin OD |

------- |

|

Fin thickness |

0.3mm |

|

Fin Pitch |

26FPI/28FPI/30FPI/36FPI/43FPI |

|

Fin Height |

less than 1.6mm |

Finned tubes application

Low finned tube from Hengyang is mainly used in air conditioning and refrigeration equipment in the condenser and evaporator absorption refrigeration oil cooler and other all kinds of heat exchanger, heat exchanger used in thermal power plants and nuclear power plants and evaporator, Marine switch in the condenser and evaporator used in gas turbine units and air cooler used for diesel oil industry secondary cooler and cooler waste heat recovery system in various dryer and heater used in the heat exchanger in chemical industry.

1. Heat Exchangers: Integral low fin tubes are extensively used in heat exchangers to maximize the transfer of heat between two fluids, ensuring efficient cooling or heating processes. Their high-performance characteristics make fin tube heat exchanger indispensable in industries such as petrochemicals, oil and gas, food processing, and HVAC.

2. Boilers and Condensers: In steam power plants and industrial boilers, integral low fin tubes play a vital role in improving heat transfer efficiency, contributing to higher energy efficiency and reduced fuel consumption. They are also commonly employed in condensers for efficient condensation and cooling of vapors.

3. Air Coolers: With their compact design and excellent heat transfer capabilities, finned copper tube heat exchanger is widely used in air coolers and air conditioning systems. They efficiently dissipate heat from the cooling medium, facilitating optimal temperature control in commercial buildings, data centers, and automotive applications.

4. Refrigeration Systems: Integral low fin tubes are essential components in refrigeration systems, enabling efficient heat exchange between the refrigerant and the ambient environment. These finned heat exchanger tubes aid in maintaining consistent and reliable cooling, ensuring the proper functioning of refrigeration equipment.