HENGYANG PIPING specializes in manufacturing high-performance seamless and welded steel pipes/tubes designed to exceed industrial demands. Our pipes and tubes are crafted from advanced materials including Austenitic/Ferritic Stainless Steel, Duplex/Super Duplex Steel, Nickel Alloy, Titanium, Copper, and Alloy Steel, ensuring unmatched corrosion resistance, mechanical strength, and adaptability across extreme environments.

Certified to ASTM, ASME, and ISO standards, our steel pipes meet rigorous global quality benchmarks, making them ideal for mission-critical applications in oil & gas, chemical processing, aerospace, and construction.

PRODUCT TYPES & FEATURES

1. Seamless Stainless Steel PipesManufacturing Process: Hot-rolled, cold-drawn, or extruded from solid billets for zero surface seams.

Advantages:

20% higher pressure tolerance vs. welded counterparts.

Uniform wall thickness for precision fluid/gas transport.

Available in diameters 4mm–900mm with custom thickness.

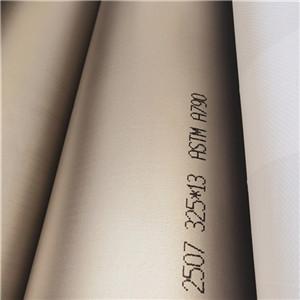

Material Grades: 304/316L, Duplex UNS S32205, Super Duplex S32750, Nickel Alloy 625/825.

2. Welded Stainless Steel Pipes

Welding Technology: ERW (Electric Resistance Welded), DSAW (Double Submerged Arc Welded), and SAW (Spiral Welded).

Advantages:

Cost-effective for large-scale projects.

Seam integrity validated by non-destructive testing (NDT).

Ideal for structural applications (e.g., A139-B, A252 spiral weld).

Material Flexibility: Carbon Steel, Alloy Steel, Copper-Nickel blends.

3. Specialty Alloy Solutions

Duplex/Super Duplex Steel: Combines high strength (2x standard stainless) with chloride resistance for offshore/chemical plants.

Nickel Alloys: Optimized for extreme heat/corrosion (e.g., Inconel® in aerospace).

Titanium Pipes: Lightweight with exceptional biocompatibility for medical/pharmaceutical use.

INDUSTRY APPLICATIONS

1. Oil & Gas: Subsea pipelines, refinery heat exchangers.

2. Chemical Processing: Acid-resistant transport systems.

3. Aerospace: Hydraulic tubing, exhaust components.

4. Construction: Structural supports, water distribution.

5. Medical: Sterile fluid transfer, surgical equipment.

WHY CHOOSE HENGYANG PIPING?

Material Expertise

Large selection of alloys: From standard SS304 to exotic Titanium Gr5.

Custom metallurgical solutions for niche requirements.

Quality Assurance

Third-party certifications (SGS, TUV) for traceability.

Full compliance with ASME B36.19M, EN 10216, and project-specific standards.

End-to-End Service

Design Support: Collaborative engineering for bespoke dimensions.

Fast Turnaround: 15-day lead time on standard inventory.

Global Logistics: Certified packaging for international delivery.