Description

Inconel 601 / UNS N06601 / W.Nr 2.4851 / Alloy 601

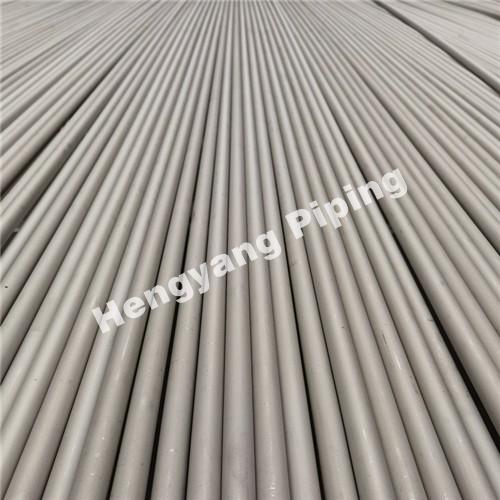

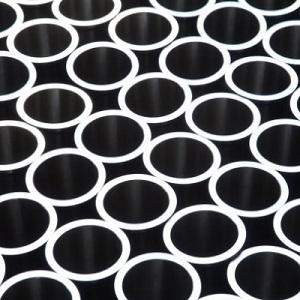

Nickel Alloy 601 Pipe and Tubing, also known as Inconel 601 Tube or Alloy 601, is a high-temperature nickel-chromium alloy that is resistant to oxidation and corrosion. It is used in various industrial applications that require exceptional heat and corrosion resistance. The Nickel Alloy 601 Pipe, with the W.Nr 2.4851 designation, is made from a combination of nickel, chromium, and iron, with small amounts of aluminum, titanium, and other elements. The result is a pipe that is highly resistant to oxidation and scaling, making it ideal for use in high-temperature environments.

Nickel Alloy 601 Pipe and Tubing is its exceptional resistance to high-temperature oxidation and corrosion. This makes it suitable for use in applications that involve exposure to high temperatures and corrosive environments. Additionally, inconel 601 tube has excellent mechanical properties, including high strength and good ductility.

Inconel 601 Chemical Composition

|

% |

Ni |

Cr |

Fe |

Mn |

C |

Si |

S |

Al |

Cu |

|

Min |

58.0 |

21.0 |

remainder |

|

|

|

|

1.0 |

|

|

Max |

63.0 |

25.0 |

1.0 |

0.1 |

0.5 |

0.015 |

1.7 |

1.0 |

Inconel 601 Physical Constants:

|

Density |

8.1 Mg/m³ |

|

Melting Range |

1320-1370 ℃ |

UNS N6601 Mechanical Properties:

|

Grade |

Tensile Strength, min, (MPa) |

Yield Strength, min, (MPa) |

Elongation in 2 in. or 50mm, min, % |

Hardness, max HRC |

|

UNS N06601 |

552 |

207 |

30 |

- |

Alloy 601 Pipe Application:

- Oil refinery components: Nickel Alloy 601 Pipe and Tubing is used in refinery components such as radiant tubes, muffles, and fixtures.

- Seawater cooling equipment: nickel alloy 601 pipe is used in seawater cooling equipment, where its corrosion resistance properties are highly valuable.

- Pulp and paper processing: In the pulp and paper processing industry, Nickel Alloy 601 Pipe and Tubing is used in the manufacturing of digesters and bleach plants.

- Processing plant for sulphuric, phosphoric and acetic acids: Inconel 601 tube from Hengyang is also widely used in the processing plant for sulphuric, phosphoric, and acetic acids.

- Gas scrubbing plant: Nickel Alloy 601 Pipe and Tubing is used in the manufacturing of scrubbers, absorbers, and ducting systems. Its exceptional corrosion resistance properties make it ideal for use in such applications.

If you are looking for wholesale Nickel Alloy 601 Pipe and Tubing from trusted supplier, welcome to contact us for more information!