Description

Nickel-chromium alloy 625/ UNS N06625/ W.Nr. 2.4856/ Inconel® 625

UNS N06625, also known as Inconel 625, is a nickel-chromium-molybdenum alloy with excellent resistance to corrosion and excellent strength at high temperatures. W.Nr. 2.4856 is the European standard reference for this alloy.

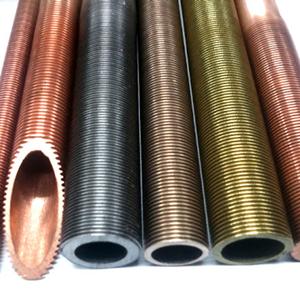

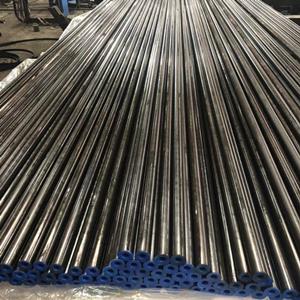

Alloy 625 pipe features

Inconel 625 pipe is often used in applications such as heat exchangers, valves, piping systems, and other critical components in high-temperature and corrosive environments. Its unique properties make it an ideal choice for use in the nuclear industry, where extreme conditions can be found.

As a supplier and distributor of seamless/welded stainless steel pipes, Hengyang offers the highest quality UNS N06625/W.Nr. 2.4856 Inconel 625 tubing. Our pipes and tubes are manufactured to the highest standards to ensure they meet all your industrial needs. We guarantee that our alloy 625 tubes will provide exceptional performance and longevity for many years to come in a variety of applications.

Inconel 625 Chemical Composition

|

% |

Ni |

Cr |

Fe |

Mn |

C |

P |

Si |

S |

Al |

Ti |

Mo |

|

Min |

58.0 |

20.0 |

|

|

|

|

|

|

|

|

8.0 |

|

Max |

|

23.0 |

5.0 |

0.5 |

0.1 |

0.015 |

0.5 |

0.015 |

0.4 |

0.4 |

10.0 |

|

% |

Co |

Nb + Ta |

|

|

|

|

|

|

|

|

|

|

Min |

|

3.15 |

|

|

|

|

|

|

|

|

|

|

Max |

1.0 |

4.15 |

|

|

|

|

|

|

|

|

|

UNS N06625 Physical Constants:

|

Density |

8.44 Mg/m³ |

|

Melting Range |

12900-1350 ℃ |

Inconel 625 Pipe Application:

1. Poutlion Control: Nickel alloy 625 tubing is used in poutlion control equipment, which is essential in chemical and petrochemical industries. These tubes are capable of withstanding high pressures and temperatures, making them ideal for this application.

2. Offshore Oil and Gas production: Inconel 625 pipes are used in offshore oil and gas production, where they can withstand the corrosive effects of seawater and harsh environments. These tubes are used in various applications, such as downhole components, tubing hangers, and subsea pipelines.

3. Petroleum Refining: Alloy 625 pipes are used in the petroleum refining industry, where they can withstand the harsh conditions that exist in this industry. Inconel 625 seamless tubing are used in applications such as heat exchangers, furnace components, and catalytic cracking units.

4. Chemical Processing: Inconel 625 seamless pipe is used in chemical processing industries, where they can withstand the corrosive effects of chemicals and high temperatures. These tubes are used in various applications, including reaction vessels, heat exchangers, and storage tan.

5. Marine: UNS N06625 pipes are used in marine applications, where they can withstand the corrosive effects of seawater and high temperatures. These alloy 625 seamless pipes are used in applications such as heat exchangers, valves, and piping systems.

6. Nuclear Industry: Nickel Alloy 625 tubes are used in the nuclear industry, where they must withstand extreme conditions, including high temperatures and corrosive environments. These tubes are used in various applications, such as reactor components, heat exchangers, and fuel element spacers.

Nickel Alloy 625/ Inconel 625/ UNS N06625 is available in wide variety of shapes and forms including pipe, tube, fitting, flange, sheet, plate, round bar, forging stock, flat bar, wire, hexagon. The various forms of UNS N08825 from Hengyang Piping meet different critical standards like ASTM, ASME, DIN, EN and clients’ specification. If you are looking for high quality inconel 625 tubing for sale, welcome to contact us for more information!

Nickel-chromium alloy 625/ UNS N06625/ W.Nr. 2.4856/ Inconel® 625 Standards

|

Pipe & Tube |

ASTM B 163 /ASME SB 163 ASTM B 165 /ASME SB 165 ASTM B 725 / ASME SB 725 ASTM B 730 / ASME SB 730 ASTM B 751 / ASME SB 751 ASTM B 775 / ASME SB 775 ASTM B 829 / ASME SB 829 DIN 17751 |

|

Rod, Bar, Wire, Forging Stock and Flange |

ASTM B 446/ASME SB 446 ASTM B 564/ASME SB 564 DIN 17752 DIN 17753 DIN 17754 |

|

Plate, Sheet and Strip |

ASTM B 127 ASME SB 127 DIN 17750 |

|

Fitting (Elbow, Reducer, Tee, Cap, Stub End) |

ASTM B 366/ ASME SB 366 |