Description

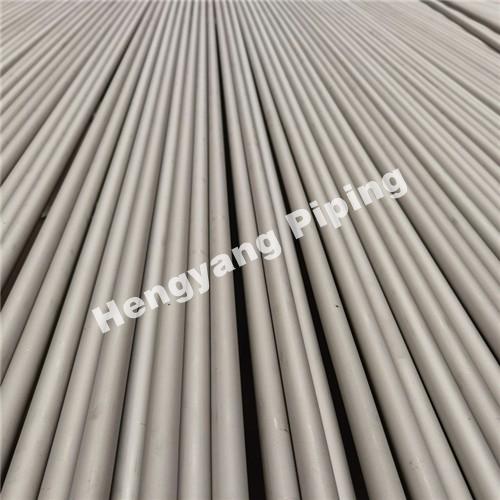

Hengyang is proud to be a trusted supplier of seamless stainless steel tubes 1.4571 / 316ti. These tubes are made from high-quality austenitic stainless steel, known for its excellent corrosion resistance and high-temperature strength.

En 1.4571 seamless stainless tubes features:

1. Corrosion Resistance: The austenitic stainless steel composition of these tubes, specifically 1.4571 / 316ti, provides exceptional resistance to corrosion in various environments, including acidic and chloride-rich conditions.

2. High-Temperature Strength: These pipes and tubes exhibit excellent mechanical properties, ensuring durability and strength even in elevated temperatures.

3. Seamless Construction: Our 316ti stainless steel tubes are manufactured using a seamless production process, which guarantees superior structural integrity and eliminates the risk of leakage.

4. Versatility: The austenitic stainless steel tubes 1.4571 / 316ti are highly versatile and can be easily fabricated, making them suitable for a wide range of applications.

En 1.4571 seamless stainless tubes applications:

1. Chemical Industry: These seamless stainless steel tubes are widely used in chemical processing plants for their excellent resistance to corrosive chemicals and high-temperature environments.

2. Petrochemical Industry: The tubes find applications in the petrochemical industry due to their exceptional resistance to sulfur-containing compounds and other corrosive substances.

3. Oil and Gas Industry: Seamless stainless steel tubes 1.4571 / 316ti are utilized in offshore platforms, refineries, and pipelines for their corrosion resistance and structural integrity.

4. Food and Beverage Industry: These tubes are commonly used in food processing equipment, breweries, and dairy plants due to their hygienic properties and resistance to food acids.

5. Pharmaceutical Industry: The high corrosion resistance and hygienic properties of these tubes make them ideal for pharmaceutical manufacturing processes and cleanrooms.

6. Heat Exchangers: The excellent thermal conductivity and corrosion resistance of these tubes make them suitable for heat exchanger applications in various industries.

7. Automotive Industry: Seamless stainless steel tubes 1.4571 / 316ti are utilized in exhaust systems, catalytic converters, and other components due to their resistance to high temperatures and corrosive gases.

Product Name

Stainless Steel Pipe and Tube

Steel

Grade

AISI:

316Ti

GOST:

08X17H13M2T 10X17H13M2T

EN:

1.4571

Manufacturing

Cold Drawn/Cold Rolled

Surface

Pickled

and Passivated, Polished, Bright Annealed

Outer Diameter

6-630mm

Wall

Thickness

0.5-45mm

Length

30000mm max

End

Preparation

PE,

BE

Delivery Term

FOB, CFR, CIF, FCA

Packing

Plywood

case, in bundles

Austenitic steels are non-magnetic stainless steels that contain high levels of chromium and nickel and low levels of carbon. Known for their formability and resistance to corrosion, austenitic steels are the most widely used grade of stainless steel.

Main Grades: 304/L, 304H, 304LN, 321/H, 316L, 316Ti, 316H, 316LN, 316LMOD, 310S, 310H, 317L, 347H, 347HFG, 309S, 904L, S31254 (254SMO) etc.

Standards(Part):

ASME SA213 Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes

ASTM A269 Standard Specification for Seamless and Welded Austenitic Stainless Steel Tubing for General Service

ASTM A270 Standard Specification for Seamless and Welded Austenitic and Ferritic/Austenitic Stainless Steel Sanitary Tubing

ASME SA249 Welded Austenitic Steel Boiler, Superheater, Heat Exchanger, and Condenser Tubes.

ASTM A312 Seamless and Welded Austenitic Stainless Steel Pipes

ASTM A511 Standard Specification for Seamless Stainless Steel Mechanical Tubing and Hollow Bar

JIS G3463

JIS G3459

GOST 9941-81

DIN 17456-8599