Description

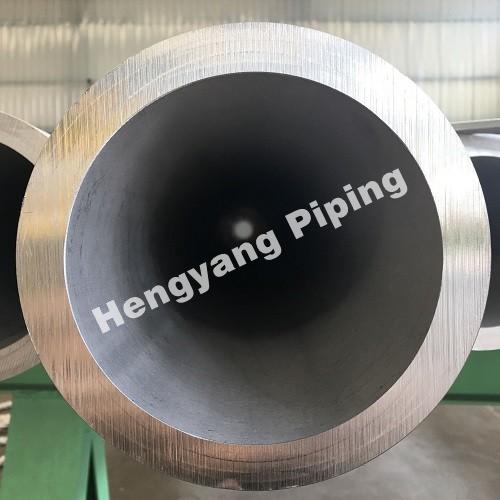

Stainless Steel Seamless Mechanical Tubing / Hollow Bar/ A511 Seamless Pipe

Stainless hollow bar, also known as hollow bar tubing, is a specialized form of stainless steel pipe with a hollow interior. It is manufactured through a seamless process, adhering to the A511 Seamless Pipe standard, which ensures high-quality and reliable performance. Stainless hollow seamless bar is designed to provide excellent strength, durability, and corrosion resistance, making it an ideal choice for various applications.

Stainless Hollow bar tubing features:

1. Seamless construction: The stainless hollow bar is produced using a seamless manufacturing process, resulting in a continuous and uniform structure without any welded joints. This enhances its strength and eliminates the risk of weak points.

2. Corrosion resistance: Made from high-quality stainless steel, the hollow bar exhibits excellent resistance to corrosion and oxidation, making it suitable for use in demanding environments and applications.

3. Superior mechanical properties: A511 Seamless Pipe possesses excellent mechanical properties, including high tensile strength, impact resistance, and fatigue resistance, ensuring its longevity and reliability.

4. Versatility: With a hollow interior, this stainless steel pipe offers versatility in terms of design and application. It can be easily machined, welded, or fabricated into various shapes to meet specific requirements.

5. Wide range of sizes: Stainless hollow bar tubing is available in a wide range of sizes, diameters, and wall thicknesses, allowing for flexibility in design and compatibility with different systems.

| Product | Seamless Steel Hollow Bar/Mechanical Tubing |

| Manufacturing | Cold Dawn/Cold Rolled |

| Material | Stainless Steel: 304, 316L,904L, S31254, 310S, 321, 316Ti, 317L, 347 |

| Duplex/Super Duplex: S32205,S32750 | |

| Nickel Alloy: Ni 200, Monel 400, Inconel 600, 625, 718, 926 Hastelloy C276, C22, B3, Incoloy 825, 800HT | |

| Surface | Pickled and passivated, polished or as per order |

| Outer Diameter | 6~630mm |

| Wall Thickness | 0.5~45mm |

| Delivery time | 25 days upon the receipt of advance payment |

| Packing | In bundles/plywood cases |

Stainless hollow bar applications:

1. Construction industry: Seamless Stainless hollow bar finds extensive use in the construction industry for structural applications such as support columns, beams, and braces. Its strength and corrosion resistance make it suitable for both indoor and outdoor projects.

2. Industrial equipment: Corrosion-resistant hollow bar from Hengyang is widely employed in the manufacturing of industrial equipment, including conveyors, machinery components, and processing systems, due to its durability and ability to withstand harsh operating conditions.

3. Oil and gas sector: Stainless hollow bar is utilized in the oil and gas industry for applications such as pipelines, downhole tools, and offshore platforms. Its corrosion resistance ensures longevity and safety in these critical environments.

4. Automotive engineering: This 304 stainless steel hollow bar is employed in automotive applications, such as exhaust systems, drive shafts, and suspension components, due to its strength, durability, and resistance to high temperatures.

5. Food processing: The hygienic properties of stainless steel make hollow bar tubing suitable for use in the food and beverage industry. It is commonly used in equipment such as tanks, piping systems, and fittings, ensuring product purity and compliance with sanitary standards.