Description

Alloy 825/ UNS N08825/ W.Nr.2.4858/ Incoloy® 825

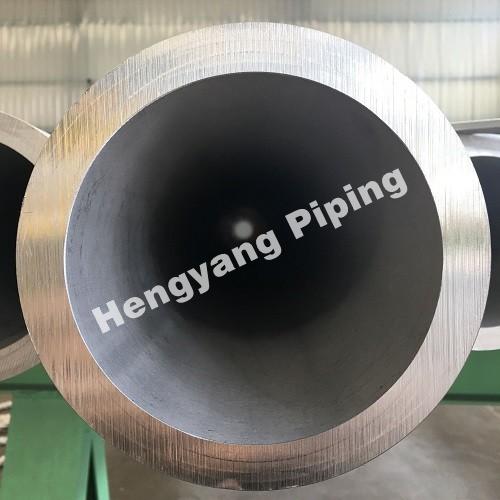

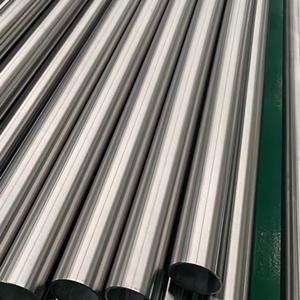

Alloy 825 tube, also known as Incoloy 825 pipe, W.Nr. 2.4858 or UNS N08825, this nickel alloy steel is a combination of nickel, chromium, and iron, with small amounts of molybdenum, copper, and titanium to enhance its resistance to corrosive environments, especially in chloride-containing media. incoloy 825 tubing is a durable and reliable material that is widely used in applications that involve harsh environments and high temperatures.

UNS N08825 Chemical Composition:

|

% |

Ni |

Cr |

Fe |

Mn |

C |

Cu |

Si |

S |

Al |

Ti |

Mo |

|

Min |

38.0 |

19.5 |

22.0 |

|

|

1.5 |

|

|

|

0.6 |

2.5 |

|

Max |

46.0 |

23.5 |

|

1.0 |

0.05 |

3.0 |

0.5 |

0.03 |

0.2 |

1.2 |

3.5 |

Features of Alloy 825 Pipe:

1. Excellent Corrosion Resistance: Alloy 825 pipe is highly resistant to corrosion, pitting, and stress corrosion cracking in various corrosive environments like nitric acid, sulfuric acid, phosphoric acid, and others.

2. High-Temperature Strength: The inconel 825 tube can withstand high temperatures up to 550°C (1020°F) and still maintain its excellent mechanical properties.

3. Good Weldability: Incoloy 825 pipe can be easily welded with various welding processes, including gas tungsten arc welding, gas metal arc welding, and shielded metal arc welding.

Incoloy® 825 Physical Constants:

|

Density |

8.19 Mg/m³ |

|

Melting Range |

1370-1400 ℃ |

Alloy 825 Tube Application:

1. Chemical Processing Equipment: Alloy 825 pipe is used in the chemical processing industry for making process vessels, reactors, tanks, and other equipment that need to be resistant to corrosion.

2. Heat Exchanger Tube UNS N08825: Incoloy 825 tubing is commonly used as heat exchanger tubing in various industries like chemical processing, oil and gas, and power generation.

3. Pollution Control: Alloy 825 seamless pipe is widely used in pollution control systems due to its excellent corrosion resistance, widely used in scrubber systems for removing harmful gas emissions from power plants and other industrial facilities.

4. Petroleum Refining: Inconel 825 pipe is used in petroleum refining applications due to its ability to withstand highly corrosive environments, commonly used in heat exchangers, piping systems, and other equipment that comes into contact with sulfuric acid, hydrochloric acid, and other corrosive substances.

5. Offshore Oil and Gas Production: The incolony tube is widely used in offshore and onshore oil and gas production, where corrosion-resistant materials are needed to withstand harsh corrosive environments.

* Marine: W.Nr.2.4858 is used in marine applications, including seawater cooling systems, desalination plants, and offshore platforms.

* Acid Production: Incoloy 825 tubing is commonly used in the production of acids such as sulfuric acid, phosphoric acid, and nitric acid due to its excellent resistance to corrosion. Incoloy 825 pipe fittings are used in heat exchangers, piping systems, and other equipment that come into contact with these corrosive substances.

* Nuclear Fuel Reprocessing: Incoloy 825 seamless pipe is commonly used in nuclear fuel reprocessing applications due to its ability to withstand highly corrosive environments. It is used in equipment such as storage tanks, piping systems, and heat exchangers that come into contact with radioactive materials and corrosive substances.

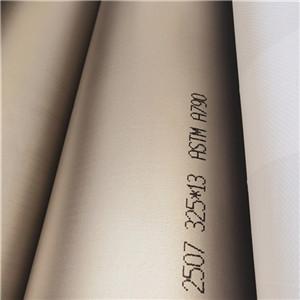

Alloy 825 for sale is available in wide variety of shapes and forms including pipe, tube, fitting, flange, sheet, plate, round bar, forging stock, flat bar, wire, hexagon. The various forms of UNS N08825 from Hengyang Piping meet different critical standards like ASTM, ASME, DIN, EN, ISO and clients’ specification. For detailed information about customized pipe and fittings, please contact us!

Alloy 825/UNS N08825/W.Nr.2.4858 Standards

|

Pipe & Tube |

ASTM B 163/ ASME SB 163 ASTM B 423/ ASME SB 423 ASTM B 704/ ASME SB 704 ASTM B 705/ ASME SB 705 ASTM B 751/ ASME SB 751 ASTM B 775/ ASME SB 775 ASTM B 829/ ASME SB 829 DIN 17751 ISO 6207 |

|

Rod, Bar, Wire, Forging Stock and Flange |

ASTM B 425/ ASME SB 425 ASTM B 564/ ASME SB 564 DIN 17752 DIN 17753 DIN 17754 ISO 9723 ISO 9724 ISO 9725 |

|

Plate, Sheet and Strip |

ASTM B 424/ ASME SB 424 ASTM B 906/ ASME SB 906 DIN 17750 ISO 6208 |

|

Fitting (Elbow, Reducer, Tee, Cap, Stub End) |

ASTM B 366/ ASME SB 366 |