Description

Inconel 718 UNS N07718/W.Nr. 2.4668/ Alloy 718

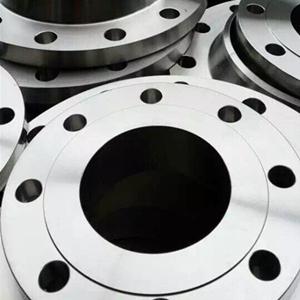

Inconel 718 tubing is a high-strength and corrosion-resistant material that is commonly used in the aerospace, gas turbine, and oil and gas industries. It is a nickel-chromium alloy that also contains significant amounts of iron, niobium, and molybdenum, which give it exceptional mechanical properties even at high temperatures. Inconel®718/Alloy 718 is available in wide variety of shapes and forms including pipe, tube, fitting, flange, sheet, plate, round bar, forging stock, flat bar, wire, hexagon. The various forms of UNS N08825 from Hengyang Piping meet different critical standards like ASTM, ASME, DIN, EN and clients’ specification.

In terms of specifications, Inconel 718 tubing has a W.Nr. 2.4668 designation and an UNS N07718 material grade. This makes it easy to identify and source the appropriate material for a particular application. Key features of Inconel 718 tubing include its excellent strength, durability, and resistance to corrosion and oxidation. It also has good fatigue resistance and can maintain its properties in extreme environments, making it an ideal choice for demanding applications.

Inconel 718 tubing is available in both seamless and welded forms, and can be used for a variety of purposes such as tubing hangers, heat exchangers, and gas turbine engine components. It is also used in forging applications due to its excellent forgeability and workability.

Inconel 718 Chemical Composition:

|

% |

Ni |

Cr |

Fe |

Mn |

C |

P |

Si |

S |

Al |

Ti |

Mo |

|

Min |

50.0 |

17.0 |

- |

|

|

|

|

|

0.2 |

0.65 |

2.8 |

|

Max |

55.0 |

21.0 |

- |

0.35 |

0.08 |

0.015 |

0.35 |

0.015 |

0.8 |

1.15 |

3.3 |

|

% |

Co |

Nb + Ta |

Bo |

Cu |

|

|

|

|

|

|

|

|

Min |

|

4.75 |

|

|

|

|

|

|

|

|

|

|

Max |

1.0 |

5.5 |

0.006 |

0.30 |

|

|

|

|

|

|

|

Inconel 718 Physical Constants:

|

Density |

8.22 Mg/m³ |

|

Melting Range |

1260-1336 ℃ |

Nickel 718 tubing applications:

1. Springs and Fasteners: Inconel 718 tubing is widely used in the manufacturing of springs and fasteners due to its high strength and resistance to corrosion and oxidation. The alloy also exhibits excellent fatigue and creep resistance, making it ideal for high-temperature and high-stress applications.

2. Gas Turbine Engine Parts: Inconel 718 pipe is used in the aerospace industry for the manufacturing of gas turbine engine parts such as turbine discs, compressor blades, and casing components. The alloy's high-temperature strength, corrosion resistance, and excellent weldability make it a popular choice for these critical engine components.

3. Cryogenic Tanks: Inconel 718 seamless tube is used in the production of cryogenic tanks and other cryogenic equipment due to its excellent resistance to extreme low temperatures and cryogenic fluids. The alloy's unique combination of high strength and toughness, coupled with its ability to maintain its mechanical properties at cryogenic temperatures, make it an ideal material for these applications.

4. Firearms Production: Inconel 718 tubing from Hengyang is also used in firearms production due to its excellent strength and durability, as well as its resistance to corrosion and high-temperature environments. The alloy is commonly used in the manufacturing of firearm barrels, receivers, and other critical components.

5. Oil and Gas: Inconel 718 seamless pipe is used extensively in the oil and gas industry for a range of applications, including downhole tools, subsea equipment, and wellhead components. The alloy's excellent resistance to corrosion and high-temperature environments, as well as its high strength and toughness, make it well-suited for these harsh operating conditions.

If you are looking for wholesale Inconel 718 tubing from reliable manufacturer, welcome to contact us for more information!

Available Products and Specifications:

|

Pipe & Tube |

ASTM Code Case N-253 DIN 17751 |

|

Rod, Bar, Wire, Forging Stock and Flange |

ASTM B 637 /ASME SB 637 ISO 9723 ISO 9724 DIN 17752-17754 |

|

Plate, Sheet and Strip |

ASTM B 670/ASME SB670 ASTM B906/ASME SB906 ISO 6208 DIN 17750 |