Exploring the Diverse Applications of Duplex Stainless Steel

Stainless steels are highly valued for their exceptional resistance to corrosion, achieved through the manipulation of various alloying elements within their composition. They are categorized into several types, including austenitic, ferritic, martensitic, duplex, and precipitation hardened stainless steels. This article will specifically delve into the history, classification, properties, and applications of Duplex Stainless Steel.

Duplex stainless steels exhibit a unique two-phase microstructure consisting of both austenitic and ferritic steel components. The mechanical properties of duplex stainless steel are contingent upon the proportions of ferrite and austenite within the composition. The predominant alloying elements, apart from iron, in the widely utilized 2205 grade, encompass Chromium (21-23%), Nickel (4.5-6.5%), and Molybdenum (2.5-3.5%).

The concept of duplex stainless steel emerged in the 1930s, despite facing challenges in maintaining its chemistry due to limitations in manufacturing techniques of the time. Nevertheless, it found applications in various industries. Significant advancements occurred with the introduction of decarburization in the 1960s, making the practical manufacturing of duplex stainless steel viable. It was during this period that Duplex 2205, recognized as the backbone of duplex grades, was developed. The 1980s marked the emergence of even more superior grades known as Super and Hyper duplex, capable of withstanding extremely corrosive environments. These advancements paved the way for the integration of duplex stainless steel into the oil and gas industry.

Properties of Duplex Stainless Steel

Corrosion Resistance:

Duplex stainless steel grades exhibit corrosion resistance properties that are equal to or even superior to those of austenitic grades. Their higher chromium content, combined with molybdenum, provides enhanced resistance to pitting and crevice corrosion. The Pitting Resistance Equivalent Number (PREN) is utilized to assess the grades based on their pitting corrosion resistance. A higher PREN number indicates higher resistance to pitting corrosion.

Stress Corrosion Cracking (SCC) Resistance:

While austenitic grades are prone to stress corrosion cracking (SCC), ferritic grades demonstrate greater resistance to this phenomenon. Duplex stainless steels offer improved SCC resistance compared to austenitic grades but are inferior to ferritic stainless steel grades in this aspect. In duplex stainless steel grades, SCC typically begins in the austenitic region but is halted at the ferritic crystal structure boundary, thereby preventing crack propagation and increasing operational uptime.

Mechanical Strength

Duplex Stainless steels have higher mechanical strength than austenitic grades and ferritic grades. It permits use of thinner sections and helps in weight reduction. Machining of duplex stainless steel is difficult and slower compared to austenite, owing to its higher mechanical strength.

Welding

Welding duplex stainless steel presents challenges compared to austenitic steel. It necessitates precise control over heat input and cooling rate to prevent the formation of undesirable intermetallic phases.

Advantages of Duplex Stainless Steel over Austenitic Counterparts:

1. Higher Strength: Duplex stainless steel offers higher strength, enabling the use of thinner gauges. This is particularly advantageous when lighter fabrications are desired.

2. Immunity to Commodity Price Fluctuations: Stainless steel prices are largely influenced by the price of nickel, a primary commodity. Duplex stainless steel contains relatively low nickel content, making it less susceptible to fluctuations in commodity prices.

Both of these factors contribute to making duplex stainless steel relatively more affordable while still offering superior properties for specific applications.

Applications and Uses of Duplex Stainless Steels

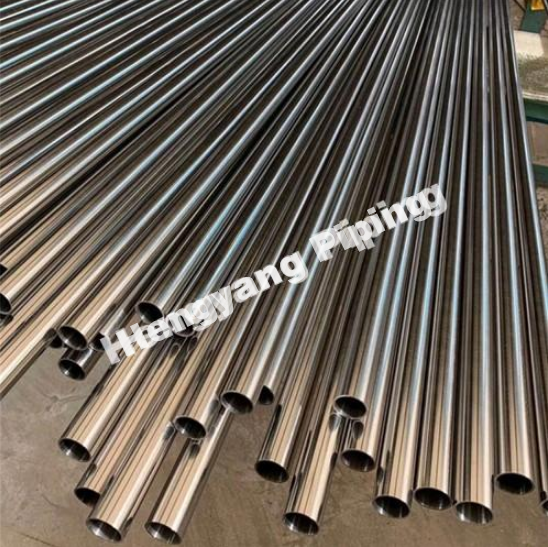

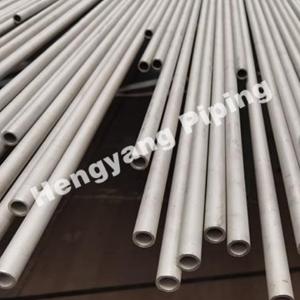

Chemical processing, transport and storage – pressure vessels, tanks, piping, and heat exchangers

Oil and gas exploration and processing equipment – piping, tubing, and heat exchangers

Marine and other high chloride environments

Pulp and paper industry – digesters, bleaching equipment, and stock-handling systems

Cargo tanks for ships and trucks

Food processing equipment

Biofuels plants