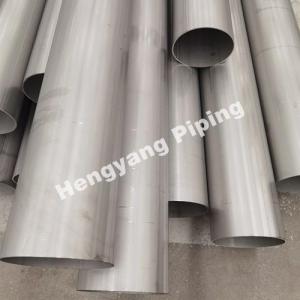

Understanding Duplex Stainless Steel Type 2205: A Comprehensive Guide

Duplex stainless steel type 2205, also known as UNS S32205/S31803, is a highly versatile and widely used grade of stainless steel renowned for its exceptional combination of corrosion resistance, high strength, and cost-effectiveness. Its name, "duplex," signifies its dual-phase microstructure, consisting of approximately equal parts of austenite and ferrite phases, resulting in a unique set of properties not typically found in other stainless steels.

Composition:

Duplex stainless steel type 2205 primarily consists of:

Duplex stainless steels are a family of alloys characterized by a two-phase microstructure consisting of both ferritic and austenitic phases. The 2205 variant, also known as UNS S32205 or EN 1.4462, comprises approximately 22% chromium, 5-6% nickel, 3% molybdenum, and a balanced amount of other essential elements such as nitrogen, manganese, and iron.

1. Chromium (Cr): Contributes to its excellent corrosion resistance, forming a protective oxide layer on the surface.

2. Nickel (Ni): Enhances toughness and resistance to corrosion.

3. Molybdenum (Mo): Increases the material's resistance to pitting and crevice corrosion.

4. Nitrogen (N): A key alloying element that improves the steel's strength and corrosion resistance.

Properties:

Corrosion Resistance:

- General Corrosion Resistance: Duplex 2205 exhibits superior resistance to various corrosive environments, including chloride-induced stress corrosion cracking and pitting corrosion.

- High Resistance to Chloride: Ideal for applications in marine environments, chemical processing, and offshore oil and gas industries due to its ability to withstand chloride-rich conditions.

- Resistance to Localized Corrosion: The alloy's composition provides resistance against crevice and pitting corrosion, often surpassing that of austenitic stainless steels.

Mechanical Properties:

- High Strength: Duplex 2205 offers significantly higher strength compared to conventional austenitic stainless steels, allowing for lighter constructions and cost savings without compromising performance.

- Toughness: Maintains good ductility and impact strength, even at low temperatures, making it suitable for various structural applications.

- Fatigue Resistance: Demonstrates excellent fatigue strength, crucial for components subjected to cyclic loading.

Heat Resistance:

- Moderate Heat Resistance: While not as heat-resistant as some austenitic grades, duplex 2205 offers adequate performance at moderately elevated temperatures, making it suitable for many industrial applications.

Fabrication and Weldability:

- Good Weldability: Duplex 2205 can be readily welded using common techniques, though precautions must be taken to maintain its corrosion resistance and mechanical properties.

- Machinability: Presents challenges in machining due to its high strength but can be machined using appropriate methods and tools.

Applications:

Duplex stainless steel type 2205 finds widespread use across various industries due to its versatile properties:

- Oil and Gas Industry: Pipelines, offshore platforms, and components exposed to corrosive drilling environments benefit from its corrosion resistance and strength.

- Chemical Processing: Equipment handling corrosive chemicals, such as reactors, heat exchangers, and storage tanks, benefit from its resistance to various corrosive media.

- Desalination Plants: Due to its ability to withstand chloride-rich environments, duplex 2205 is used in desalination equipment.

- Structural and Architectural Applications: Bridges, structural components, and architectural features benefit from its high strength and corrosion resistance.

- Pulp and Paper Industry: Used in digesters, bleach washers, and other equipment exposed to corrosive pulping processes.

- Automotive and Transportation: Some automotive components and transportation infrastructure utilize duplex 2205 for its strength and resistance to corrosion.

Conclusion:

S32205 Duplex stainless steel stands out as a reliable and cost-effective material offering a unique blend of strength and corrosion resistance. Its dual-phase microstructure and well-balanced alloying elements make it a preferred choice across diverse industries where demanding conditions require robust materials capable of withstanding corrosive environments while maintaining structural integrity.