Guide to Austenitic Stainless Steels

Austenitic stainless steels are versatile and popular materials, known for their corrosion resistance, high-temperature strength, and suitability for the fabrication process. Austenitic stainless steel is widely used across most higher-specification industrial and domestic applications.

Austenitic stainless steel is a non-magnetic grade of stainless steel that contains high levels of chromium and nickel, and low levels of carbon. It has a face-centered cubic crystalline structure, which gives it good ductility, toughness, and excellent formability.

Austenitic stainless steel is the most widely used grade of stainless steel. The most common composition is 18% chromium and 8% nickel, also known as 18/8-steels. 304 stainless steel, often referred to as "18-8" stainless steel, contains manganese (2% max.), and a small amount of carbon, silicon, phosphorus, and sulfur.

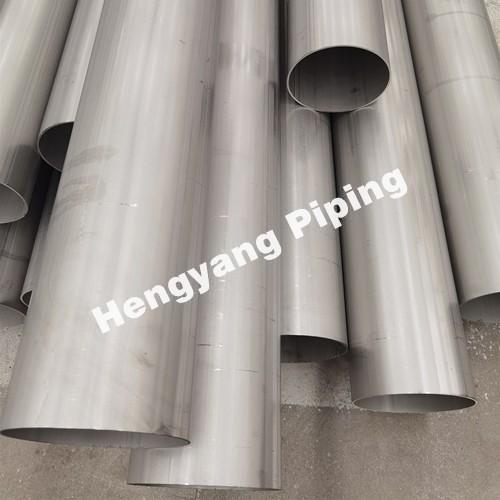

Austenitic stainless steel is used in many industrial applications, including:

Piping, Flanges, Fittings, Sink rolls, Bearings, Impellers, Shaft sleeves, Pressure vessels, Heat exchangers, and Centrifuge bowls.

Characteristics of Austenitic Stainless Steel

Austenitic stainless steel exhibits numerous positive characteristics that drive demand. This category constitutes approximately three-quarters of the global stainless steel market, valued at $93.69 billion in 2018 and projected to grow at a CAGR of 5.2 percent by 2025.

Strength at High Temperatures: Austenitic stainless steel can withstand extreme temperatures, ranging up to approximately 1900°F depending on the grade. Some grades may experience deformation, softening, or loss of strength starting at 800°F.

Cold Workability: Austenitic stainless steels cannot be hardened through heat treatment; instead, their strength can be increased via cold working or reduction. Cold working involves shaping the metal without heating it and can be achieved with austenitic stainless steel. Annealing followed by rapid cooling, or quenching, can restore the metal to its original state. Cold-rolled stainless steel offers several advantages, including improved surface finish, hardness resistance to crack propagation, and enhanced strength.

Low Thermal Conductivity: Heat transfers slowly through austenitic stainless steel, whereas ferritic stainless steel exhibits higher thermal conductivity.

Formability: Austenitic stainless steel is highly formable, making it versatile for various applications.

Cold working austenitic stainless steel enhances its strength but reduces its ductility. Different stainless steels offer advantages in different applications; however, austenitic stainless steel is more susceptible to stress corrosion cracking compared to ferritic stainless steel.

Austenitic stainless steel is typically non-magnetic, while ferritic stainless steel is usually magnetic. The magnetic properties of stainless steel can vary, influencing applications such as refrigerator construction.

Common Grades of Austenitic Stainless Steels

The 300 series stainless steel comprises a larger subgroup and finds a much broader range of applications compared to the 200 series. Among the most common austenitic stainless steel grades are those belonging to the 300 series.

Type 304

Not only is it the most popular type of austenitic stainless steel, but 304 also ranks as the most common type of stainless steel overall. With high nickel and chromium content, this grade offers a desirable combination of strength, corrosion resistance, and fabricability.

Type 316

As the second most used grade of stainless steel, 316 shares many similarities with 304. However, the addition of Molybdenum enhances its corrosion resistance and increases its heat resistance.

Type 310

Featuring high chromium and medium nickel content, this grade exhibits exceptional resistance to oxidation and corrosion, making it suitable for high-temperature applications.

Type 321

Titanium is added to this grade along with a significant amount of carbon, providing increased corrosion resistance when exposed to chemicals at high temperatures.

Austenitic Stainless Steel vs. Martensitic Stainless Steel

Martensitic Stainless Steel is characterized by high carbon content and low nickel content, imparting exceptional strength, hardness, and wear resistance. With a body-centered cubic (BCC) crystal structure, it exhibits lower ductility compared to Austenitic Stainless Steel. This type of stainless steel is commonly employed in applications demanding high strength and wear resistance, such as knives, tools, and turbine blades.

Austenitic Stainless Steel and Martensitic Stainless Steel have different compositions and microstructures, which give them different properties. Austenitic Stainless Steel is highly corrosion-resistant, ductile, and formable, while Martensitic Stainless Steel is highly wear-resistant, hard, and strong. The choice between the two types of stainless steel depends on the specific application requirements and conditions.