The Purpose of Bright Annealing Process for Stainless Steel

The bright annealing process of stainless steel serves two main purposes: achieving the desired metallographic structure by eliminating work hardening and producing an oxide-free bright surface. This process involves a detailed examination of these two critical aspects and their respective roles.

1. Achieving Excellent Microstructure in Stainless Steel by Eliminating Hardening

The primary purpose of a bright annealing furnace is to heat stainless steel products under a protective atmosphere, tailoring the microstructure according to the specific application requirements. The bright annealing process for stainless steel differs depending on the desired microstructure, which varies across different types of stainless steel.

For 300 series austenitic stainless steel, the typical heat treatment process is solution treatment. During heating, carbides dissolve into the austenite. The material is heated to 1050-1150°C and held at that temperature briefly, allowing the carbides to fully dissolve into the austenite. It is then rapidly cooled to below 350°C, forming a homogeneous supersaturated solid solution of single-phase austenite. The key aspect of this process is rapid cooling, which requires a cooling rate of 55°C/s to pass quickly through the precipitation temperature zone (550-850°C). Prolonged heat exposure can cause grain growth, adversely affecting the surface smoothness of the stainless steel.

In contrast, the heat treatment for 400 series ferritic stainless steel involves a lower heating temperature of around 900°C. This treatment focuses on annealing and softening through slow cooling. Martensitic stainless steel also uses annealing but may incorporate stepwise quenching and re-tempering heat treatment methods.

Given the significant differences in the heat treatment processes between the 300 and 400 series, a bright annealing furnace must offer extensive and flexible cooling options. Typically, advanced bright annealing furnaces utilize strong convection cooling in three independent cooling sections, allowing for precise control of airflow and cooling rates across the width of the stainless steel strip, ultimately ensuring the desired shape and microstructure.

Another crucial aspect of heat treating cold-rolled stainless steel strips is maintaining uniform distribution across the strip's width and length. In muffle tube and muffle-type bright annealing furnaces, uniform heating is achieved by circulating heated air spirally around the strip. Consistency in line speed within the heating furnace is vital to ensure uniform microstructure along the strip's length. Advanced vertical bright heat treatment furnaces are equipped with adjustable roller tension devices at both the inlet and outlet, which help regulate the strip's speed and maintain the necessary tension. This precise control ensures the production of stainless steel plates that meet specific quality requirements.

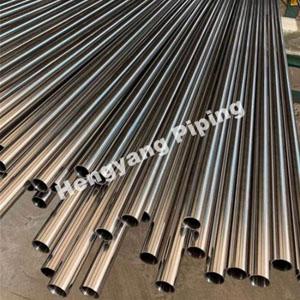

Bright Annealed Precision Tube

2. Make the stainless steel band get the bright surface without oxidation

Generally, bright annealing is the heat treatment of stainless steel strip under H2 protective atmosphere. And stainless steel processing technology to meet the requirements of BA panels, we must strictly control the bright furnace protection atmosphere, purity, shall avoid oxidation. And what about the oxidation under the protective atmosphere of H2?

The chemical composition of stainless steel strips typically includes elements like iron, chromium, nickel, manganese, titanium, and silicon. During the annealing process, the oxidation of iron and nickel is less significant, but the oxidation of chromium, manganese, silicon, and titanium occurs within the heating temperature range. This oxidation can affect the surface brightness of the stainless steel strip. Specifically, chromium oxidation can lead to a reduction in chromium content on the surface, decreasing the stainless steel's corrosion resistance. To prevent oxidation of chromium and titanium, particularly when the chromium content is 17% to 18% and titanium is 0.5%, the hydrogen (H2) dew point must be kept below 60°C during heating at temperatures between 800°C and 1150°C.

It is also crucial to maintain the protective atmosphere inside the furnace and ensure the purity of the gas. A well-sealed muffle furnace, free from contaminants, helps maintain a clean atmosphere, essential for protecting the stainless steel. Vertical furnaces, with their entrance at the bottom, are generally more stable in maintaining furnace pressure, reducing the risk of air intake compared to horizontal furnaces. However, it is vital to ensure that the sealing boxes at the inlet and outlet, as well as the tension rollers and feeding rollers, meet stringent sealing standards, with leakage kept to a few parts per million (ppm). This prevents oxygen and water vapor from entering the furnace and ensures the protective gas remains uncontaminated.