A Simple Guide to Duplex and Super Stainless Steel Pipes

Stainless steel has revolutionized various industries with its exceptional corrosion resistance and durability. Among the different types of stainless steel, duplex stainless steel and super stainless steel have gained prominence for their unique properties and applications in critical environments. This guide aims to provide a comprehensive overview of these remarkable materials, shedding light on their composition, properties, and versatile uses.

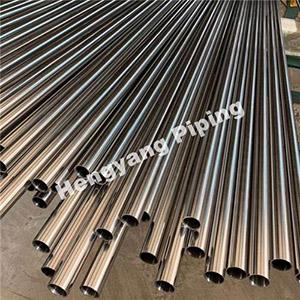

Understanding Duplex Stainless Steel

Duplex stainless steel is a class of stainless steel that combines the attributes of both austenitic and ferritic stainless steels. This hybrid composition results in a material with enhanced mechanical properties and exceptional corrosion resistance, making it suitable for challenging environments.

Composition

The composition of duplex stainless steel typically includes higher levels of chromium (ranging from 18% to 28%) for corrosion resistance, nickel for stability and strength, and molybdenum for improved pitting resistance. The balance of these elements creates a microstructure that consists of both austenitic and ferritic phases, contributing to the material's unique properties.

Properties

1. Corrosion Resistance: Duplex stainless steel boasts superior resistance to various forms of corrosion, including pitting, crevice corrosion, and stress corrosion cracking. This property is especially advantageous in environments containing chlorides, acids, and other corrosive agents.

2. Strength and Toughness: The combination of austenitic and ferritic structures results in a material with higher mechanical strength and toughness compared to traditional stainless steels.

3. Stress Corrosion Cracking Resistance: Duplex stainless steel exhibits remarkable resistance to stress corrosion cracking, making it an excellent choice for applications where exposure to both corrosion and mechanical stress is a concern.

4. Weldability: While duplex stainless steel is generally more challenging to weld than austenitic stainless steels, advancements in welding techniques have made it increasingly weldable without compromising its properties.

Applications

1. Oil and Gas Industry: Duplex stainless steel pipes find extensive use in offshore oil platforms, subsea pipelines, and other components exposed to harsh marine environments.

2. Chemical and Petrochemical Industry: The material's resistance to corrosive chemicals and high temperatures makes it a valuable asset in chemical processing plants.

3. Desalination Plants: The chloride resistance of duplex stainless steel is crucial in desalination plants where exposure to saline water is constant.

4. Structural and Mechanical Components: Its strength and corrosion resistance make it suitable for structural applications in construction, as well as for manufacturing pipes, tubes, and fittings.

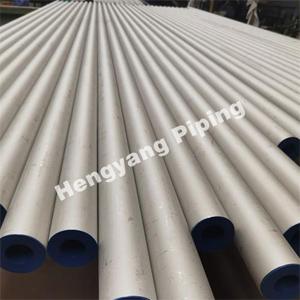

Understanding Super Stainless Steel

Super stainless steel, also known as high-performance stainless steel, is a category of stainless steel that goes beyond the capabilities of traditional stainless steels. It is designed to provide exceptional performance in extreme environments where corrosion, high temperatures, and mechanical stress are simultaneously present.

Composition

Super stainless steel comprises a complex combination of alloying elements, including high levels of chromium, nickel, molybdenum, and additional elements like tungsten, copper, and nitrogen. These elements work in synergy to create a material with unparalleled properties.

Properties

1. Extreme Corrosion Resistance: Super stainless steel demonstrates exceptional resistance to a wide range of corrosive agents, including acids, alkalis, and chloride-containing environments.

2. High Temperature Resistance: The alloy's high chromium and nickel content enable it to maintain its structural integrity and corrosion resistance even at elevated temperatures.

3. Mechanical Strength: Super stainless steel possesses remarkable mechanical strength, allowing it to withstand high mechanical loads and pressures.

4. Creep Resistance: The material's ability to resist deformation under prolonged exposure to high temperatures and stress is a crucial factor in its high-performance capabilities.

Applications

1. Aerospace and Aviation: Super stainless steel is used in aircraft components, engine parts, and exhaust systems due to its ability to withstand high temperatures and corrosive gases.

2. Nuclear Industry: The combination of corrosion resistance and mechanical strength makes super stainless steel suitable for nuclear reactors and other nuclear applications.

3. Chemical Processing: In chemical plants where aggressive chemicals and elevated temperatures are present, super stainless steel serves as a reliable material choice.

4. Medical Implants: The biocompatibility and corrosion resistance of super stainless steel make it suitable for medical implants and instruments.

Conclusion

In the realm of stainless steel, duplex and super stainless steel pipes stand as marvels of engineering, each with its own set of exceptional properties and applications. Whether it's the robustness of duplex stainless steel or the superlative performance of super stainless steel, these materials continue to redefine the possibilities in industries where corrosion resistance, strength, and durability are paramount.

ZHEJIANG HENGYANG PIPING EQUIPMENT CO., LTD. ( HPE) is the global window of Chinese reputed manufacturers, dealing professionally in exporting business for them, exporting all the products manufactured by them, including seamless I welded pipes and tubes, fittings and flanges, round bars and forgings. As well as manufacturing to orders, the company also keep a wide range products in stock which have been strictly inspected and are ready for quick shipment.

The main materials the company adopts are stainless steel, (super) duplex steel, corrosion-resistant alloys, nickel alloys.

If you want to read more information about Duplex and Super Stainless Steel Pipes, just visit -->https://www.hengyangpiping.com/Contact-us-hengyang-piping-stainless-steel-pipe-and-tube-supplier-distributor-stockist.html